Tuesday

May282013

by  Bishop Hill

Bishop Hill

Bishop Hill

Bishop Hill Environmentalism brings you forest clear-cutting

May 28, 2013

May 28, 2013  Energy: biofuels

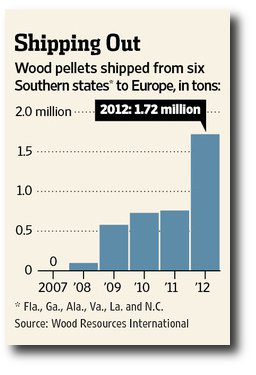

Energy: biofuels Thanks to the efforts of environmentalists such as Friends of the Earth and WWF, forests in the southern USA are being clearcut in an effort to meet European demand for wood pellets - a demand that has been driven by biomass power generation.

Reader Comments (101)

Billy Liar and Martin A: is this the same Professor Phil Jones who cannot cope with Excell spreadsheets?

If it is, he must have a wonderful imagination!

May 29, 2013 at 4:51 AM Alexander K

AK - please do not malign the Prof. He can cope with Excel spreadsheets with no problem at all (at the elementary level).

It is only when it comes to using advanced features such as using the built-in regression analysis function that he has to ask for help from an assistant.

Wait till the Quacktitioner gets his seat on the throne, King Charles will have all his subjects back in caves.

Thank you, Sandy S (May 28, 2013 at 6:51 PM), though I think Dave Salt (May 28, 2013 at 5:20 PM) expressed the same ideas I mooted far more succinctly. There is a clue in my moniker as to how careful I want to be.

Richard Drake (May 28, 2013 at 6:53 PM), re your links: “…not more than about 13%...” If that is the sort of sloppy thinking being nurtured in Oxford, there really is no hope.

Regarding the shipping of this wood; I have no idea how big the largest bulk carrier is, but would expect it to be in the region of 150,000 – 200,000 tonnes deadweight. A ship this size would burn approximately 70 tonnes of fuel oil per day (present cost, circa $800 /tonne); trip length would depend on load port and discharge port, but would not be less than 10 days, and may be up to 15. Add to these figures the fact that the demand will raise shipping rates (but let’s assume that the chartering settles at a low of $25,000 per day), then I fail to see how it can possibly be considered viable.

Finally I think it was Private Eye who pointed out that for Drax, and Drax alone, to convert to wood chippings, it would require clearing a forest the size of Yorkshire every year. This is the problem with Greens - they possess no ability to see reality, they just imagine it as they think it ought to be (thanks, ZT).

May 28, 2013 at 7:43 PM | Entropic Man

The result is that UK coal production has dropped by almost 50% in two months.

On one of the main terrestrial TV channels yesterday, or was it the day before, there was a news item about how our remaining steam trains (run mainly for railway enthusiasts and tourists) are under threat because they are finding it increasingly difficult to get reliable deliveries of coal to keep them going. That is despite the fact that there is still plenty of coal underground in Britain. But, as Entropic Man has pointed out, there are very few mines.

Could our steam trains run on wood pellets from Florida, I wonder?

Mike says...King Charles will have all his subjects back in caves.

I know that your comment is T.I.C but where is King Charles going to build all the caves 'cos there aren't enough to go round at the mo!

May 28, 2013 at 11:42 PM | Registered CommenterMartin A

Martin, somewhere buried deep in one of my blogs (forgotten exactly where) are the details of a betting system circulating a few decades ago based on backing the winners (or in some cases runners-up) of certain selected races on their next outing. Detailed results of the previous five years were given showing a strike rate of around 75%, I seem to remember.

Needless to say in the first year the system was publicly available it fell flat on its face by which time its inventor was no longer advertising his wares — at least not under the same name and address!

We have to assume that in his case this was a major work of fiction (for which he is to be admired since the research necessary to identify a reasonable cross-section of races that fulfilled the criteria to whatever standard he was aiming for must have been extremely time-consuming) with profit from the mugs who fall for such things as the sole object.

In the case of the Met Office's hindcasting, the existence of powerful computers would have made the exercise a little less exhausting but with every day that passes I come closer to the conclusion that this also was a major work of fiction with profit from the mugs (in this case politicians) who fall for such things as the sole object.

May 29, 2013 at 8:59 AM | Radical Rodent

/////////////////////////////////

Whilst there are some very large bulk carriers, the typical bulk carrier is no where near as large as the size you suggest.

Handysize is upto about 35,000dwt, handymax, up to about 60,0000, panamax upto about 80,000 dwt. I guess that typically one would see 40,000 to 50,000dwt as a general purpose bulk carrier. Fuel consumption would be considerably lower than you suggest, but nonetheless there would be substantial CO2 (and sulphur even with low sulphur bunker fuels) emitted. Sea transport is not particularly green.

Chartering costs depend upon the market. In a strong market, it could be considerably higher than the rates you suggest (perhaps $40,000 per day), in a weak market perhaps more like $16,000 per day.

One of the main issues is how is the wood to be transported? Logs are quite a dangerous cargo and do a lot of damage to ships (due to their heavy size and difficulties in handling). It is much easier to transport pellets/wood chips which are easy to load and can be discharged by vacuation or grabs. The speed of handling both ends will be far quicker.

Obviously it costs more to ship in wood for burning, than to supply coal from a near by mine (Drax was built on a minefield). However, if coal is not locally available and has to be shipped in, then there is considerable costs inherent is shipping in the coal. I do not know where this comes from (Poland, South Africa, Australia are probably the main suppliers and I would not expect to see coal shipped in from as far away as Australia).

There's plenty of useless bio mass in west minister and the houses of parliament, why import?

I dunno about plant life, I thought it was mainly pond life in Parliament.

I can assure you that the forests in Florida, Georgia, Virginia and North Carolina are just fine and are not being clear cut, I fly over them regularly. Tree farming is big business here on the East coast and we are more than happy to sell our wood by-products to our friends the Brits, there is a more than enough to meet the demand. Should the supply begin to dwindle, rest assured that the price will go up and the Canadians will step in. But really, burning wood and wood by-products is a primitive and dirty way to generate heat, more suited to third world countries. Natural gas is more efficient keeps the air much cleaner, but I suppose that you already know that?

Years back, a colleague and I started a study to determine the precise nature of bullshit, because there was so much of it around.

One key finding (the study was never completed) is that the highest quality of bullshit comes from those who believe their rubbish with the utmost sincerity.

The Met Office researchers, from Slingo down, sincerely believe that their super computer models reveal the reality of what is going to happen.

As I said in an earlier comment, the Met Office could have put a stop to the nonsense at an early stage. But they (the top management and the Hadley Centre) were set up to chuck fuel on the bonfire - which they did, far and away exceeding expectations. And, for the top management, reaping rewards of salary and status far beyond what is usual in scientific research.

This Baltic Exchange document says 100mt of fuel oil per day for a VLCC.

http://www.balticexchange.com/media/pdf/tce/vlcctcecalculationprocess.pdf

Typical speed of one of these vessels is 13 to 14 knots, so a 3,000-mile trip would take 9.6 days and would consume 960 tonnes of fuel oil. I think they use a bit of marine diesel too but I don't have a cite for how much so I'll refrain from guessing, other than to note that it's quite a bit less.

Add in a few extra tonnes for loading and unloading and you're looking at around 1,200 tonnes of fuel oil. VLCCs are probably larger than the typical vessel for this sort of cargo - I'd think a Suezmax would be about as big as they would get.

richard verney/radical rodent

Richard thanks for confirming my thoughts on burning wood.

Both, isn't the size of bulk carrier dependant on the lowest maximum size allowed by the docks at either end of the journey? The old Clan Line had just such a restriction because of the size of the docks in Calcutta. I can't find much information but Grangemouth the closest port to Cockenzie is limited to

Dry cargo: 187.00 metres loa x 27 40 metres beam x 7.70 metres draft.

@ SandyS

Correct, the maximum vessel size for any given route is limited to whatever will fit the berths at each end. You cannot load a VLCC and take it to a Suezmax port. The exception is somewhere like Coryton, where you can take in a VLCC as long as it is only part-loaded. This entails a two-port discharge with part of the cargo being dropped off en route somewhere else. In effect, the size, beam etc are permissible but the draft is restricted.

That's a fantastic comment by Radical Rodent 28/5/13 at 4.28. I nodded along in agreement to every sentence.

Anyone see the BBC Breakfast feature on this matter yesterday, presented by Roger Harrabin..? Clearly he found himself in a cleft stick - not sure whether to support it or rubbish it - but of course at one point he had to come out with the line... 'As the climate warms...' at which point my wife was quite surprised at the language I was shouting at the poor inoffensive telly (although she's getting used to it)...

Anyway - this is clearly the politics of the lunatic asylum...

I agree it is a nonsense from an enery efficiency point of view, but these will be timberland plantations, not virgin forest.

No different to exporting beef.

May 29, 2013 at 12:05 PM | Justice4Rinka

////////////////////////////

I have about 30 years experience in shipping so I am able to shed a little light on this.

We are not talking about VLCCs (which carries oil cargoes).

As SandyS notes, the maximum size of vessel is limited by the physical restrictions encountered on the voyage. This can be canals where canals are transitted and hence why some common class of vessels are referred to as Suezmax, or Panamax. It can be the restrictions imposed by the ports of calls, such as maximum berth size, or maximum draft at one or other port.

I do not know enough about the ports of call, but if SandyS is right that one of the ports of discharge is Grangemouth and if he is right on the particulars that he gives then we are talking about a small vessel, much smaller than the typical bulk carrier that I had in mind (which I thought would be 40,000 to 50,000dwt which would have had a draft of say about 11 to 13m).

Of course, all vessels are different in their details, albeit there will be broad similarities between various size bands.

I attach a brokering advert for a small bulk carrier (25,000 dwt, 155m length). See http://www.shipbrokerlink.com/ShipSale/ShipSaleView.aspx?idx=16122

You will note the vessel's main characteristics; 25,000dwt on 10m draft, 155m length, 12.5kts on 23tpd. So even a vessel that size would be unable to comply with the port restrictions that Grangemouth imposes.

Personally, I would have thought it uneconomic to utilize a small bulk carrier. I consider it far more likely that a 40,000 to 50,000dwt bul carrier would be used. I attach the particulars of a fairly typical 54,000dwt bul carrier http://www.gmilimited.com/docs/vessels/MV%20ATHOS.pdf

You will note her main characteristics, 54,000dwt on about 12m, 190m length, 13.8kts on 33tpd. Incidentally, her cargo carrying capacity will be less than 54,000mt.

To utilize such a vessel would require some other discharge port. One that permits a draft of say not less than 12.5m so that there is some safety margin. Usually, there is some tolerance over and above the maximum draft of a port (depends upon the state of tide etc and how quickly a vellel can proceed, and it is usually possible to adjust ballast etc so that the vessel is trimmed differently to allow a vessel to squeeze in and out but there comes a limit when that is not possible and if over draft cargo will have to be transhipped which is expensive).

Surely all the ships with empty containers that were used to ship all those British-manufactured goods to the USA could be used at very low cost to return full of wood chips?

How many Jags to we sell over there?

Hi Richard

Yes, canal transit is obviously relevant too.

Grangemouth is of course an oil port as well, and IIRC has two VLCC berths and about 2 million barrels of crude storage. It may be that the terminal used by oil ships is not the same one as that used by other traffic, of course.

187m LOA is not much at all, and IIRC most Panamax (which I'd call LR1), Suezmax (which I'd call LR2) and VLCC (which some apparently call LR3) come in at between 200 and 270m; the greater capacity of the larger vessels over the smaller arising from beam and draft, rather than from length.

If a power station is relying on ships as small as 25,000 or 50,000DWT - which as you note is not the same as payload - then presumably they are stations that used to import fuel oil via that conduit. Oil product ships are typically of those sizes, but this means that fuel-inefficient ships are being used to import an inefficient fuel. It really is Wonderland.

Rog Tallbloke is onto this, I see:

Link

BTW, if wood is 5 times less energy dense than coal, won't they need 5 times as much of it? Given that the coal was delivered more or less continuously by rail wagons, that looks like a probable point of failure...

Now all we need to do is adopt the leaf as our unit of currency......we will all become tremendously rich, but may encounter some inflation problems. However, thos problems can be cured by clear-felling large tracts of forest. - and voila! we also get lots of biomass to burn and go back to the Dark Ages (or Medieval Times).

Douglas Adams was right, we are the descendents of the Golgafrinchams and not the apes.

Hi Justice4Rinka

I rather doubt that the power company will get involved in the chartering of vessels since if it does so, it will need a shipping department not simply to charter in vessels (on voyage, or time trip basis) but also to give operational input (directions, making berthing arrangements, appointing port agents, bunker agents, co-ordinating with stevedores etc).

I suspect that the power company will purchase the biomass on CIF basis (cost, insurance, freight). The purchase price will include an element to cover the shipping costs. If this is so, then the seller will wish to make a profit not simply on the biomass but also on the freighting costs. He is likely to charge at least 10% over the actual/estimated costs of shipping the product. Indeed, he has to charge more than the estimated costs since he will wish to build in a safety margin just in case there are delays and mishaps on the voyage.

What a lot of people might not realise is that when shipping goods, the shipowner usually gets paid a ballast bonus. In shipping, the voyage is usually regarded as starting when the vessel proceeds on her way to the load port and the shipowner will wish to be remunerated for the time and costs of getting his vessel to the load port.

There are too many unknown variables (size of vessel, ports involved etc) to make an assessment of the costs involved, but obviously we are talking about well over $1million to ship the cargo to the UK.

I don'y know how much biomass is used per month, but this will be a nice little earner for someone. Even the brokers often get paid a couple of percent commision on hire, or freight, and there may be more than one broker involved.

Martin A (May 28, 2013 at 9:53 PM):

Counterfactual history. One of the most important examples I can see since 1988. Thanks very much for spelling this out. I agree entirely.

Thank you for your expansion of the shipping theme, especially your more detailed knowledge, J4R.

I am not sure why you have settled on Grangemouth as the port for Drax, as it is in the Firth of Forth (also, the sea island for VLCCs is not suitable for dry bulkers); surely a closer port would be better. With that in mind, I am not sure if the Humber estuary has any bulker terminal; Teesport does have the facilities for large bulkers (it is/was mainly for iron ore, but wood chippings should not be too difficult to convert to), though I have no idea about rail links

The reason I picked the larger size for a bulker is that wood is not a particularly dense cargo (clue: chuck a and a lump of coal stick in the stream; which one floats away), so it would have to take advantage of transporting in, well, bulk – the bigger the ship, the better. Obviously, there are limitations imposed by the load port and the discharge port, but I am sure that both sides of the Atlantic have the facilities for large bulkers. As pointed out, the cost of each cargo will be in excess of $1,000,000; whether the charter is spot, time or bare-boat, the cost of the voyage will be for both ways, so we could actually be looking at closer to $2,000,000 for each load of 150,000 tonnes, or about $7 per tonne – and that is only the shipping costs; it does not take into account the land transport, or storage! Then there is the problem of spontaneous combustion; both wood and coal are subject to it, however, wood is by far the more likely, especially if stored in the quantities that would (no pun!) be required.

Like it or loathe it, gas is going to win out an every single scenario.

Where did my stick go? I'm sure it was there, with the lump of coal!

Obama maybe a sleeper from USFAM, an African Environmental Organisation whose aim is to bring equality to the world.

To reduce the USA to dust, mud huts and rusting shipping containers would be a means to this end.

I should 'fess up that I know bugger all about fuel traffic operations to power stations nowadays, my personal experience having been limited to oil traffic. That said, once upon a time cracked fuel oil was a common fuel for power generation, especially since it was of little use for anything else, and hence power operators must have maintained some sort of traffic function.

I presume those that use gas still do to the extent that they burn regasified LNG.

Whatever - it is clear that as the energy density of woodchips is maybe a fifth that of fossil fuel you need 5x as much it at - at least - 5x the shipping costs. In fact, more like 10x, since gas can be had from much closer at hand.

The bottom line is that it does not make sense.

Burning biomass emits more CO2 than does the burning of coal or gas. Hence UK CO2 emissions will factually rise. If the intention is to reduce the UK CO2 emissions this policy is a fail.

Since Biomass has a lower calorific value compared to coal or gas, more has to be handled and hence the handling costs will be more.

The UK can theoretically supply its own coal, but cannot presently supply biomass in the required quantities. As far as Drax is concerned, the infra-structure for coal is already in place, for Biomass it needs to be built. This may include the building of special and dedicated port facilities (which could be costly if ports have to be dredged and larger berths constructed to handle larger vessels).

The costs of the supply of coal is cheaper than the costs of supply of biomass.

Then there is the conversion costs of Drax itself.

There is neither a green/environmental case for biomass (more CO2 emissions, the needless desecreation of forests, more pollution in the carriage from supply to destination), nor is there an economic case (biomass is more expensive and the costs of suply are more than those of coal or gas).

This really is one of the most stupid political decisions. The stupidity is reinforced by the fact that 2 new coal powered stations are being build each week in developing nations (China and India etc such that worldwide CO2 emissions is on an upward tragetory), and even Germany, which is a country where green has gone mad, are building 20 to 23 new coal powered stations.

In the light of that, the UK government should simply keep Drax in service as is. To do so would not only lower UK CO2 emissions, lower the cost of electricity for industry and consumer a like, it also gives local employment to miners etc.

The UK government will come to regret this decision as the full impact of higher energy prices comes home to roost, not simply in the consumer pocket but also in making industry uncompetitive leading either to job loss, or the requirement for state subsidies to off-set the costs of energy in energy intensive industries. One way or the other the UK tax payer pays for this farce, and the ripple effect is large.

And it so nearly didn't happen (cough):

http://www.bbc.co.uk/blogs/paulhudson/2012/02/drax-axes-plans-to-build-new-b.shtml

Harvesting subsidies faster than trees.

Five months later:

http://www.businessgreen.com/bg/news/2194307/drax-aims-to-go-coalfree-after-biomass-subsidy-review

Back in Oct 2011:

http://www.draxgroup.plc.uk/media/press_releases/?id=155789

End of year results 2012:

http://www.draxgroup.plc.uk/files/page/26/2012_FYR_FINAL.pdf

RR,J4R,RV

I think Grangemouth was my example rather than definitive knowledge, I couldn't find any information on the ports involved. Many years ago I used to use the Forth crossing at Kincardine Bridge so the Refinery/Port/Power Station grouping was familiar to me. If more power stations than Drax are to be converted to wood burning then this close proximity would appear to be a logical choice.

Other ports seem to have similar restrictions as most freight is containerised now and wood chippings would be shipped by other means places like Felixstowe didn't seem appropriate. Most British docks (Glasgow, Liverpool, London, Bristol, Dundee) have closed now so choice is limited anyway.

Sorry if I mislead the discussion.

Referring back to the cost of shipping, no-one seems to have noticed that my basic maths has let me down – we are talking about $13-$14 per tonne, not $7! That makes the scheme even more risible.

btw, I have come to the conclusion that the stream I chucked the stick and lump of coal into was very fast flowing. That is where my stick went...

NBY: to give Paul Hudson his due, he does seem to only report the story, and abstains from making comment. The comments also seemed to be more balanced than can often be found on this and other sites, though at least one falls into the “CO2 is pollution” trap. It also looks as though it isn’t only climate scientists who can make wildly wrong predictions:

(It has since been shown to be one of the quietest.)

I am surprised that the enviroloons haven’t leapt on that as more evidence of the extent of man-made climate change – of the Sun!

To add a note to J4R and richard verney — and not disagreeing with either of them ...

Drax and the Selby coalfield were joined at the hip. As were Cockenzie and Monktonhall, Lynemouth (aluminium smelter) and Ellington, Longannet and Longannet colliery, Kincardine and the Fife coalfield ...

Originally Longannet received its coal direct from the colliery by conveyor belt. When it opened in 1970 it was the largest coal-fired power station in Europe consuming 4.5m tons of coal a year and with storage capacity for 2m tons.

Drax used to receive its coal by merry-go-round from the local pits but now has most of it imported and delivered by rail from ports as far flung as Tyne and Hunterston — good news for the railways; less so for the electricity consumer. In 2011 it used over 9m tons of coal.

I find these figures quite frightening, but then big numbers in fields I don't fully understand have always scared me, and I don't see how it is ever going to be possible to guarantee the continuity of raw material supply that will be necessary. I also fail to comprehend a mindset that prefers to import an inefficient generating material at high cost from abroad rather than a locally sourced, somewhat less inefficient, material.

These facilities were built where they were because they would be sitting on top of their raw materials. They still are. What are we thinking?

Mike Jackson:

9 million tons, eh? If J4R is correct with the assertion that wood energy density is on fifth that of coal, Drax would then require 45 million tons of wood chippings. That works out at about 300 ship-loads (assuming ships of 150,000DWT), i.e. roughly one ship every 1.2 days. With a journey round-turn of at least 3 weeks (say, 10 days each way, one day loading, 2 days (ha! – such optimism!) discharging), that is going to require at least 25 150,000 tonne bulkers on permanent contract – and that is only for 1 power station! Charter rates will go through the roof!

No matter how you look at it, gas wins every single time.

Er, what do they do with the wood ash?

Potash fertiliser is an obvious answer but given that one cord of wood can produce around 50lb of ash and I don't know how many cord-equivalents Drax would burn in a year but I imagine several(!) I think they would need to look at other uses. Perhaps they could bury it underground somewhere. Or send it to landfill?

I note from the Met Office website, that Richard Betts, Head of the Climate Impacts strategic area, is also the Editor of the Journal of Environmental Investing, (http://www.metoffice.gov.uk/research/our-scientists/science-leaders)

http://thejei.com/index.php/JEI/about/displayMembership/2.

This journal is sponsored by Solør Bioenergi, "a leading market player in the generation and distribution of renewable energy based on wood and wood waste."

http://solorbioenergi.com/production-and-distribution-of-biofuel/

@May 30, 2013 at 11:55 AM | Radical Rodent

/////////////////////////

I had been assuming that the voyage would be a one way voyage.

It is expensive to send a ship accross the Atlantic in ballast; this is not normally done. One would expect the ship operator to collect a back cargo so that the ship was a revenue earner on the return voyage. Obviously, the UK could not fill such a ship. on a regular basis, since we don't export enough. Cargoes would have to be picked up in Europe and taken to South America, Mexico, USA, Canada. I am not sure what Europe exports in sufficient quantities. The possibilities of back cargoes may well influence what size of vessel is employed, and also whether the ship is geared or gearless (gearless ships are cheaper to hire and operate than geared vessels).

if there is no back cargo, one is nearly doubling the shipping costs. I have not checked your $13 to $14 per tonne freighting costs. In those figures, have you includied the costs of the return leg? If you have not, it may be that your figures require substantial upgrading.

I myself have not looked at the costing since there are presently too many unknown variables to permit making a reasonable voyage estimate.

Presumably someone has given a thought as how all this biomass is going to be imported in sufficient quantities and at the costs involved.

Re: QUANTITY OF MATERIAL REQUIRED

I have not checked this data, and it may be biased since it comes from a Biomass web site. See the attached comparisons of the calorific content of various fuels.

http://www.biomassenergycentre.org.uk/portal/page?_pageid=75,20041&_dad=portal&_schema=PORTAL

You will note that commercial coal has just under twice the calorific value of wood pellets and about 2.5 times the calorific value of wood chips. Of course, much depends upon the seasoning of the wood, the lower the moisture content the higgher the calorific value and, of course, the more expensive the purchase price.

If those figures are correct, it does not appear to me that one will need 5 times as much biomass as coal. Probably it is more like 2 to 2.5 times as much biomass, than is required with coal.

Sorry to post in piece meal fashion.

I seem to recall reading that not all the boilers in Drax were being converted. If memory serves me, it was only about half or 2/3rds of the boilers that are being converted to biomass burning.

May be long term they will convert some more, but I suspect that that will not happen for a long time. May be I am being cynical, but I suspect that it has something to do with the subsidies. They get a full subsidy but only incur the costs of converting half the boilers.

Drax in its converted form is not going to produce as much power as it did when burning coal. That is going to have an adverse impact upon base load capacity.

Richard:

Because of the specialisation of the ships, a lot of them do have returns trips in ballast; you are right, I suspect you would be hard-pressed to find enough bulk cargo in Europe to fill the required number of bulk carriers – you can’t count BMWs, as bulkers are basically the wheelbarrows of the sea; chuck it in and dig it out – also, you would need to factor in the time for loading and discharging the return cargo, and then time from the western discharge port to the load port (they are unlikely to be the same, or even close to each other). Should you choose that line, then considerably more ships would be required to ensure delivery of 1 load per day. As you say, there really are too many variables involved to make accurate costings of the shipping, but $2million (or >$13 per tonne) would be a good rule of thumb for the round trip. Of course, we still have not taken into account costs of cutting, prepping (chipping, drying, etc), and land transport.

One other important factor to consider in the ship is the problem of auto-combustion of the wood. I do not know what is the maximum depth recommended to avoid that problem, but I suspect that it will be much less than the 18 metres, or so, required to fill a hold on a 150,000DWT bulker.

If a bunch of non-specialists such as ourselves can realise the utter futility of this scheme, you have to wonder about the motives of those to whom the government is listening.

Once again, apologies for the piece meal posting.

One point that has not been considered but which is relevant to the shipment is whether the biomass is a 'deadweight' cargo, or a 'volume' cargo.

Bulk cargoes are often catagorised as being either 'deadweight' when the limiting factor as to how much cargo can be loaded on board a ship is the weight of the cargo, or a volume cargo, when the limiting factor is how much space the cargo occupies.

Say one has a 50,000dwt ship. It may have a number of holds which are say 15 metres high. if one is shipping say steel plates, or rebars, due to the density of the material, the vessel's full deadweight capacity may be reached when steel in the hold is stacked some 3 or so metres high. The vessel is unable to compl;etely fill her holds because with 3 metres of steel in her holds she is right down at her maximum draft.

on the other hand, if a cargo of cotton is being shipped, the holds may be full to the brim so that there is no physical space on board to load more, but the vessel may be sailing only at about half draft, she may have on board no more than about 25,000 tonnes of cotton.

In the above example, steel is a deadweight cargo because it is the weight of the cargo, not the volume of the holds that limits intake quantity. Cotton on the other hand is a volume cargo, since it is the volume that the cargo occupies, and not its weight, which limits how much cargo can be loaded.

One issue that arises in the case of the shipment of biomass is whether it is a deadweight cargo, or a volume cargo. It is not a very dense cargo; it's density is only about 1/10th that of coal. Whilst I have not properly investigated, this leads me to suspect that biomass is a volume cargo.

If that is the case, if one had a vessel that had a cargo carrying capacity of 50,000 tonnes, one would not be able to ship as much as 50,000 tonnes since the available volume of the ship's holds would be fully utilized before that tonnage was reached. The same would apply if the vessel had a cargo carrying capacity of 150,000 tonnes, one would not be able to ship the full weight before the vessel had no further space in her holds with which to accomodate further cargo.

The upshot of this is that if biomass is a volume cargo more ships would be required to deliver the required tonnage for burning, and the cost of transport would be more expensive.

As I said above, there are presently too many unknown variables to make a realistic stab at the costings.

Radical Rodent

I have only briefly considered the logistics, but it appears to me to be a nightmare.

First one has to know how much cargo is required per month. I am not clear on this.

Second, one needs to know how the cargo will be loaded, and how it will be discharged? The only quick method of loading is direct from silo, and quick discharge would be by way of vacuators. If it has to be loadecd and discharged by grabs, it is going to take a long time. Now I do not know enough about the characteristics of the cargo and to what extent it is free flowing (it will need to be free flowing if it will be loaded directly from silo, and discharged by vacuators). I am not up to date on this, but seem to recall that wheat loading in Canadian ports (direct from silo/spout loading) was approximately 3,000 tonnes per hour, say 60,000 to 75,000 tonnes per day. With grabs, you would be lucky to load 10,000 tonnes per day. Dishcarge rates could be radically less especially if being directly loaded onto trucks, or railway wagons.

Third you need to know about port facilities. Berth size, draft etc. You also need to know about storage facilities. At discharge, will the cargo have to be discharfged on to trucks/wagon because of insufficient silo storage space. One has to bear in mind that silos will soon become full unless they are continually being emptied, to free up space, and how are they going to be emptied. How many ships can the port/berth accomodate, what is the waiting time and turn around times. Will there be port congestion, and if so what will happen? How many trucks/wagons can the port accomodate? All of this is linked.

Fourth, there are not many dry cargo bulk carriers of 150,000 dwt. I am far from convinced that bulk carriers of that size can be handled in British ports (I have only been involved in tankers. and car carriers, and container vessels in British ports, so I am not familiar with general bulk cargo handling capabilities). I suspect that it will be necessary to employ smaller vessels, but perhaps a new dedicated terminal will be built to accomodate larger vessels. If so, wh is going to bear that expense?

Fifth, whilst, I have seen cases where dry cargo ships have been chartered in to perform a repetitive contract of affreightment involving one way carriage and returning in ballast, this is rare in the dry cargo market (not rare in the tanker market). One has to work out the cost effectiveness of sailing an empty vessel accross the Atlantic (depends upon the size but could costs $1/2million to $1million depending upon current rates and bunker consumption). If one is hiring a vessel for say a year, you are essentially suggesting that 1/3rd of the expense will be paid just to have the ship empty. This may be the most cost effective scenario, but someone would need to examine the alternatives because we are talking many many millions in having an empty ship.

Sixth, it depends on what basis the cargo is being bought. If the cargo is being bought CIF (cost insurance freight), the Seller will make the shipping contract. He may voyage charter the ship from USA to England. The ship will be redelivered by the Seller once discharge is complete in the UK and the shipowner will have his vessel back to trade as is where is. The Seller will then have to charter in another vessel for the next voyage on similar basis. That might be more cost effective than chartering in a number of vessels on long term time charter and operating those vessels empty for one third of the time. In shipping time is money, and the parties frequently argue over just a few hours lost here or there.

I am not entirely sure that I know what you mean about auto combustion in relation to the depth of stow. But you are right that this type of cargo can get hot and can ignite. There will be specifications laid down as to the maximum moisture content on loading, the maximum temperature of the cargo on loading. There will be criteria for vetilating the cargo, possibly requiring carriage under a CO2 blanket. I haven't checked, but I am reasonable sure that the cargo will be covered by the dangerous goods code which will deal with the requirements for safe carriage. The ship will have to be fitted with appropriate automated fire fighting equipment.

There is much in the logistics to consider (at both the load port and the discharge port). It is clear that shipping this material will be expensive. Someone is going to earn a lot just puttig the contracts together, I once knew a shipbroker who landed on his feet. He put together a 20 year sale contract for Nigerian oil and the shipment of the cargo. He earned 2.5% commission on both the sale of the oil and the chartering of the ships. The gross contract was worth about $40 million a month (probably a lot more now given the rise in price of crude) and he was getting paid 2.5% of that each month. He gave up his job as a ship broker and merely oversaw the performance of that contract. Once the 20 year deal had been signed, it involved just a few hours work each month. There is an opportunity for someone to do something similar with this biomass contract. Someone could earn a lot of money just on commissions.

Richard Verney:

Precisely, which is the point of my last paragraph:

p.s. know any way we could team up to get the contract?

As a seafarer in a previous life time, I thoroughly enjoyed reading this thread. There is little in it that contradicts my experience and observations, for I worked in two Panamax vessels (sister ships, 64.000DW) and one Handymax (geared, 24.000DW). I got to transport bulk goods (coal, ore, grain and, yes, iron bars, even) to twenty different countries, before I turned 20.

Just to illustrate the kind of goods, ships and distances we covered, here is a sample:

1-Iron bars, Handymax, from Turkey to China

2- Copra, Handymax, from Philippines and Malaysia to Italy and Holland

3- Wheat, Panamax, from France to Pakistan

4- Coal, Panamax, from South Africa to Portugal

5- Wheat, Panamax, from UK to South Korea

Of the above, the ones that are relevant to the discussion would be numbers 2 and 5. Copra (coconut pellets/chips?) isn't unlike wood chips in terms of bulk transportation, but, unlike wood, coconuts must be carried to Europe. It makes economic sense to be using even a smaller geared vessel to carry it. In Manila, the ship was anchored in the bay and the goods were loaded from barges by using the ship's cranes. It took 14 days to fill half the cargo holds... which, excluding the working hours, gave us 7 days and nights to spend in the bars and hotels of that seedy city, if I may add gratuitously. ;-)

The economics of the trip number 5 is also mind boggling considering the fact that we made the trip from Southampton to Inchon carrying wheat. The UK was exporting food to the other side of the world! What's more, we were ordered to make the journey not through the Suez Canal but the Cape of Good Hope, and do it slowly (10-12 knts/ph). So instead of 45, we reached our destination in 55 days. The ship's fuel tank could hold approx 3000 tons fuel-oil. There were diesel tanks as well but I can't remember their size. We filled up the tanks twice during that journey; once in the Canary Islands and once in Singapore. There was talk among the crew even then whether this particular trip would be profitable for the importer or the company that chartered the vessel. I mean, why not buy the wheat from Australia, Canada or the US? The only economically rational explanation was that the Panamax ship was being used not just for transportation but as a storage facility as well.

I thought I might just throw this out there, not that anyone is interested in reading it. Now, I gotta go.

Jun 1, 2013 at 5:21 AM | sHx

///////////////////////

Hi sHx

I read your comments and experience with interest. It sounds like you had a good time.

The economics of voyage 5 appear strange, and obviously I do not know precisely what went on. On the one side one has 10 days extra hire and 10 days extra bunker consumption, but off set against that expense is the saving in the Suez canal charges (which can be quite substantial and can involve waiting time, if the ship has just missed the convoy) and the fact that one has 55 days worth of bunker consumption at eco rates as opposed to 45 days of bunker consumption at full/max consumption rates. Further, the owner may have wished to pick up bunkers or stores at Durban or other SA port because they were cheaper than elsewhere (that is just pure speculation especially since Singapore is a convenient port for those purposes).

But one possible factor is redelivery periods. Charterparties frequently have an earliest and latest redelivery time and if the charterer seeks to redeliver early or late, he faces claims for damage (or the owner may simply try and not accept early redelivery and insist upon the charterer continuing to pay hire). It may be the case that the vessel was coming to the end of her charter. There would be insufficient time to perform a further voayage post South Korea. If that is the case then if the vessel got to South Korea quicker she would be standing idle after delivery of cargo in South Korea waiting for the redelivery date to come round. If that is the case it may have been more cost effective to avoid the Suez canal fees and consume bunkers at eco rate.

Of course, I do not know. I am merely speculating and putting forward one reason.

The point that Radical Rodent was making is that the economic consideration behind shipping all this biomass from the US to UK suggests that it will be considerably more expensive than supplying the power station with coal, and that there are potentially logistical nightmares. In broad terms I agree with that, and it appears that you do not disagree.